Just Better

Why Pin High labels are better

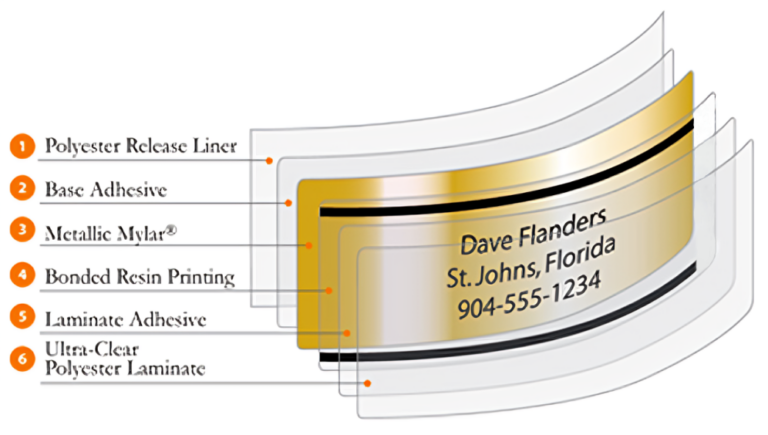

A close look at how our labels are manufactured shows why they are so durable and so popular. In a sense, each club label is like a club sandwich, with 6 distinct layers, each contributing something special to the finished product.

Before creating our label, Pin High Inc. did the research to create a flawless label. Thanks to this research, we came up with the print quality that you can see on our labels now.

1 Effortless Peel – Quick and Clean Application

A smooth, silicone-coated liner makes it easy to peel and apply each label without tearing or frustration.

2 Strong Adhesive – Secured to Play, Removed Your Way

The adhesive grips tightly to your shaft but can be removed without damaging the surface or leaving sticky residue. The labels stay secure while you play, but won’t harm your clubs when it’s time to change them. (Labels are removable after curing, though shafts should be cleaned with alcohol or other mild organic solvent before applying new ones.)

3 Premium Metallic Film – Polished and Professional

We use ultra-durable Mylar film for a metallic finish that resists fading, scratching, and wear. It is one of the strongest films available, and specially coated to accept our thermal printing process.

4 High-Contrast Printing – Crisp and Clear Lettering That Won’t Fade

We bond your custom text directly into the metallic film using high-temperature thermal printing. Although far more expensive than inkjet printing, this process provides higher contrast and much greater fade resistance.

5 & 6 Protective Laminate – Built to Last From Season to Season

A tough polyester laminate seals and protects the label, locking in print quality and guarding against moisture, scratches, and UV exposure. All 4 corners are slightly rounded to minimize peeling and allow for usage on other products with flat surfaces, such as cell phones, laptops, and much more.

Labels that stay built for the game.

Note: Mylar® is a registered trademark of Dupont Teijin Films.